Vimaq brings to the market the best presses for ecologic soil-cement brick’s fabrication. Know our market segmentation:

Civil Construction

Build your own house saving up to 45%.

Entrepeneurship

Open your business and earn money

selling ecological bricks.

Social Projects

The right choice for municipal administrations, NGOs, etc.

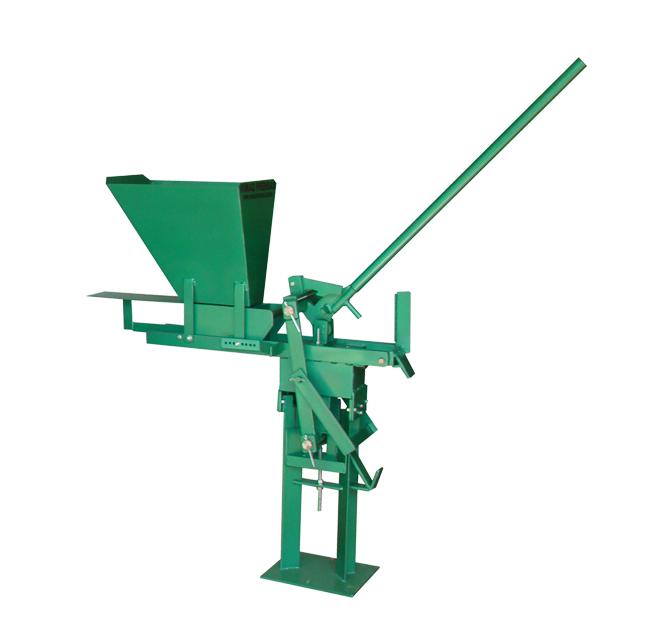

Machines

About Us

Vimaq Prensas goal is spread the ecological soil-cement brick construction concept in Brazil and other countries believing that sustentable construction systems must evolve from dreams and drawings to reality. Joinning hands with the ecological brick community, we improved our products and now we are determinated to share information about nature-friendly materials and processes.

We support architectural and urban planning social projects, academic studies and research about composites, that can be added to the brick mixture to reduce industrial wasting pollution.

Join us raising this flag, contacting us to help you to publicize and disseminate your projects, building sites photos, etc!

Or will you let them burn trees for no reason only to make ordinary bricks?

FAQ

What are the advantages in using Vimaq type soil-cement solid and hollow bricks?

They can be used together in the same wall, although the solid brick can be positioned to give more resistance in fixing closets or certain kitchen areas for instance. The hollow brick are better for conducting piping and wiring networks or columns steel rebars.

What kind of soil (Earth) is better to make soil-cement bricks?

The better soil comes from the inner layers of the soil avoiding the crust with dried materials, grass, etc. The composition 60% – 80% gravel (“sand”) and 40% – 20% clay with no contaminants. When you buy a Vimaq machine you earn a two-day instructor-led course with all information that you need to select and even correct the soil to produce bricks with good resistance, including the applicable quality tests. Besides, Vimaq offer lab results for any soil sample, by a modest fee.

Is it possible to make diferent bricks with different dimensions in the same run?

Only changing the press mold you can achieve this variation.

What are the main advantages in buiding using the soil-cement concept?

Material economy (cement, sand, steel, wood, painting, waste), labour.

It´s an ecological product with better thermal and accoustic properties.

What are the most commons brick dimensions?

(HxWxL) 2 ½” x 5”x10” is the most common dimension and is produced in the M12 Vimaq Press. The second is 3” x 6” x 12” and is produced by the M15 Vimaq Press.

Are the ecological bricks burned in furnaces?

No, they undergo the same curing process of cement with hidratation. The final product presentes a compressive strenght 3 times greater then ordinary bricks. The absence of the burning step avoid the necessary combustion of materials, as in the case of firewood ovens.

How many operators are needed in a mechanical press production setup?

The best production is achieved with 3 persons: 1 operate the press, 1 preparate the mixture and feed the machine and 1 extracts the brick and move the finished and raw material.

Why I need a grinder machine?

It brakes the clods of soil that are common in the raw material. Afterwards is used to final grind the mixture eliminating the use of screens.

What is the average net profit working with only one press?

Estimating 1000 bricks/day, 22 days/month and assuming the 2017 costs of operation and the average price in Brazil of the 2 ½” x 5” x 10” one can profit monthly around U$ 3000.00.

What is the daily production of a hand-operated press?

Starting with 1000 it can score 1500 bricks per day as the operators became more skilled.

What is the proportion soil/cement?

Usually 8 to 10 parts of soil to 1 part of cement varying with the soil quality.

How many bricks per cycle in a hand-operated press?

1 brick per cycle.

What is the 2017 F.O.B. price of 1000 bricks (2 ½” x 5”x10”)?

Around U$167.00.

What is the role of the hollow brick and the solid brick developed by Vimaq?

They can be used together in the same wall, although the solid brick can be positioned to give more resistance in fixing closets or certain kitchen areas for instance. The hollow brick are better for conducting piping and wiring networks or columns steel rebars.

How much to change the Refil plate?

The FOB price is U$ 50.00. We send by mail with instructions to install the new one that is a simple operation. The REFIL plate is a Vimaq-created part and was for long time an exclusive Vimaq’s buit-in feature while competition offered disposable presses with no wearing protection and short operation life. Now REFIL is adopted by others manufacturers.

Can I produce bricks without a grinder machine?

Yes. You can use one or two hand screens but productivity decays.

One grinder can feed two presses.

Conctact Us

![]()

![]()

vimaqprensas@gmail.com

![]()

![]()

Phone / WhatsApp:

+55 (61) 8306-1312 (Mr. Helton)